CLAD PIPES

Introducing JLC clad pipes: uniting strength, corrosion resistance, and reliability

Introducing JLC clad pipes: uniting strength, corrosion resistance, and reliability

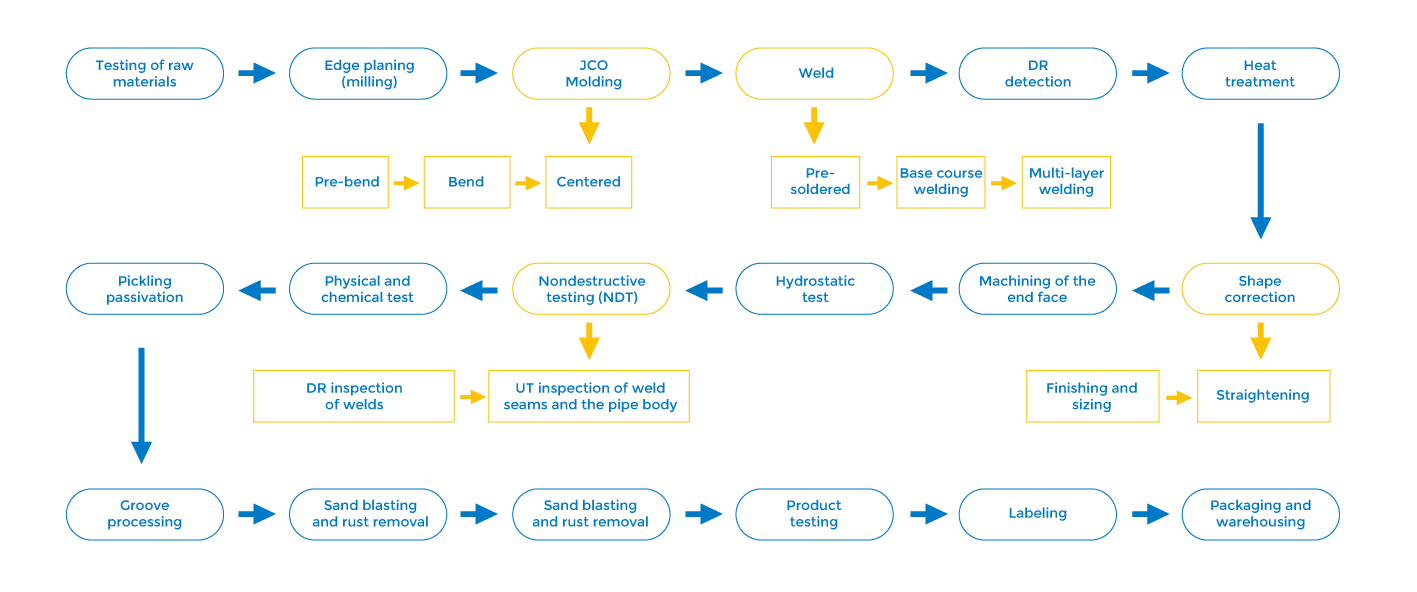

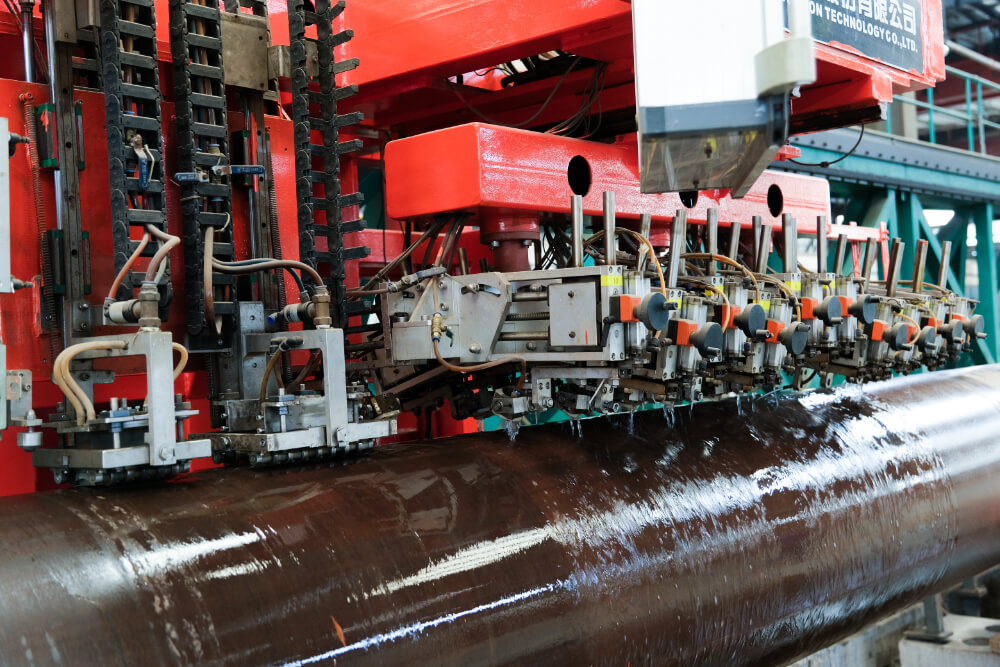

JLC Clad Pipes stand as a testament to excellence in the world of piping solutions. Crafted with utmost precision and utilizing advanced metallurgical bonding techniques, our clad pipes offer unparalleled strength, exceptional corrosion resistance, and unwavering reliability in a wide range of demanding industries and applications.

JLC Welded Pipes Division specializes in the manufacturing of a diverse range of clad pipes that are specifically designed to meet the requirements of highly challenging conditions and services.

| Pipe Diameter | DN150 ~ DN2000, Delivery of Drum combination for Diameter Greater than DN2000 |

| Manufacturing Standards | API Spec 5LD, DNV-OS-F101, GB/T37701 |

| Thickness of Cladding Material | 2 – 5mm |

| Thickness of Base Material | 8 – 65mm |

| Wall thickness Outer pipe | From 10mm to 70mm |

| Length | Up to 12 m with a girth weld 18m or 24m can be provided |

| Base Materials | Carbon Steel, Hi-Yield Grades, Low Alloy Steels |

| Corrosion Resistant Alloy | 410, 304L, 316L, 321, 254SMo, N02201, N02205, N06625, N08825, N04400, Titanium Alloy etc. |

CRA LINED PIPES, API 5L GR.X 60+3mm 825 clad (7.92mm + 3mm Clad)

NACE MR0175 AS PER DATA SHEET NO- P12512-12-99-18-1609.U/G, (Oil flow line pipeline), 12m length

Product Specification

| Nominal Pipe Size | Nominal O.D | NOMINAL W.T (TOTAL THICKNESS), mm | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NPS | mm | 08 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 |

| 6 | 168.3 | ||||||||||||||||||||||

| 8 | 219.1 | ||||||||||||||||||||||

| 10 | 273 | ||||||||||||||||||||||

| 14 | 355.6 | ||||||||||||||||||||||

| 16 | 406.4 | ||||||||||||||||||||||

| 18 | 457 | ||||||||||||||||||||||

| 20 | 508 | ||||||||||||||||||||||

| 22 | 559 | ||||||||||||||||||||||

| 24 | 610 | ||||||||||||||||||||||

| 28 | 711 | ||||||||||||||||||||||

| 30 | 762 | ||||||||||||||||||||||

| 32 | 813 | ||||||||||||||||||||||

| 34 | 864 | ||||||||||||||||||||||

| 36 | 914 | ||||||||||||||||||||||

| 38 | 965 | ||||||||||||||||||||||

| 40 | 1016 | ||||||||||||||||||||||

| 42 | 1067 | ||||||||||||||||||||||

| 44 | 1118 | ||||||||||||||||||||||

| 46 | 1168 | ||||||||||||||||||||||

| 48 | 1219 | ||||||||||||||||||||||

| 52 | 1321 | ||||||||||||||||||||||

| 56 | 1422 | ||||||||||||||||||||||

| 60 | 1524 | ||||||||||||||||||||||

| 64 | 1626 | ||||||||||||||||||||||

| 68 | 1727 | ||||||||||||||||||||||

| 72 | 1829 | ||||||||||||||||||||||

| 76 | 1930 | ||||||||||||||||||||||

| 80 | 2032 | ||||||||||||||||||||||

| Nominal Pipe Diameter and Wall Thickness | |||||||||||||||||||||||

| Specification: API Spec 5LD DNV0S-F101 | |||||||||||||||||||||||

| Production length up to 12 m | Other Diameters and wall thicknesses are available on request | ||||||||||||||||||||||

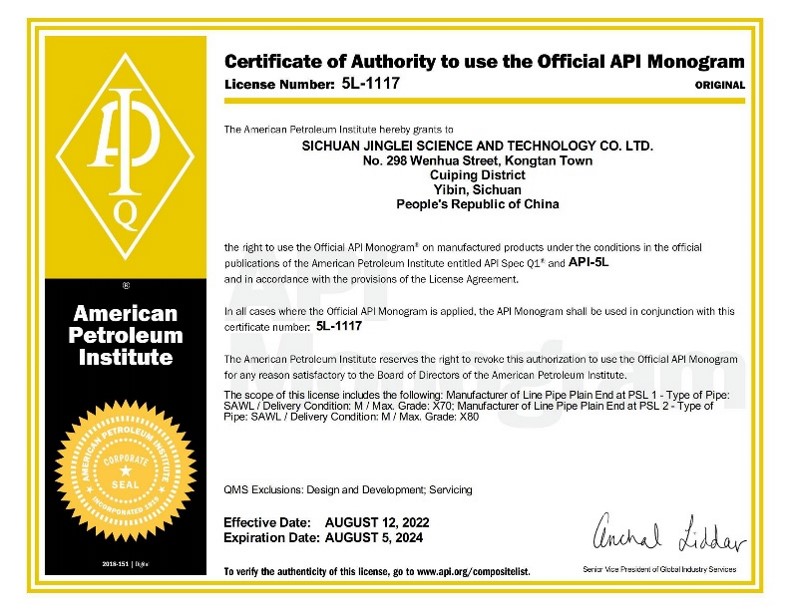

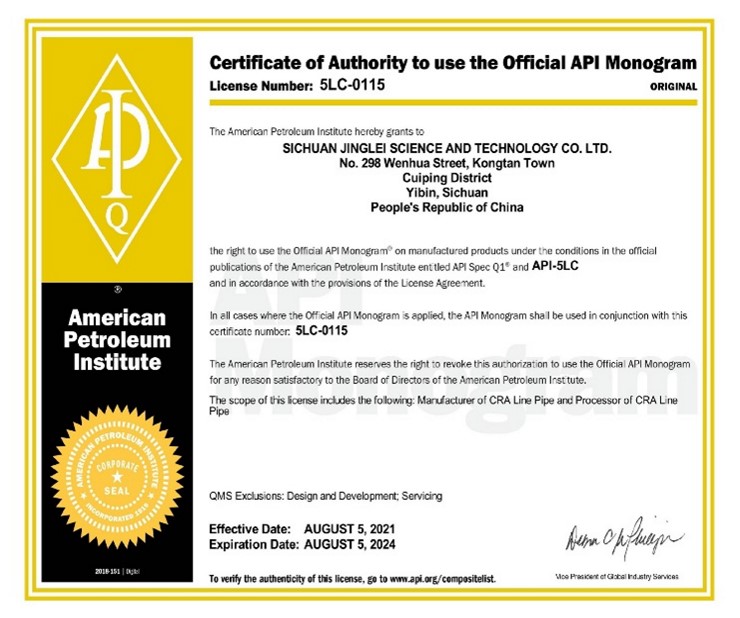

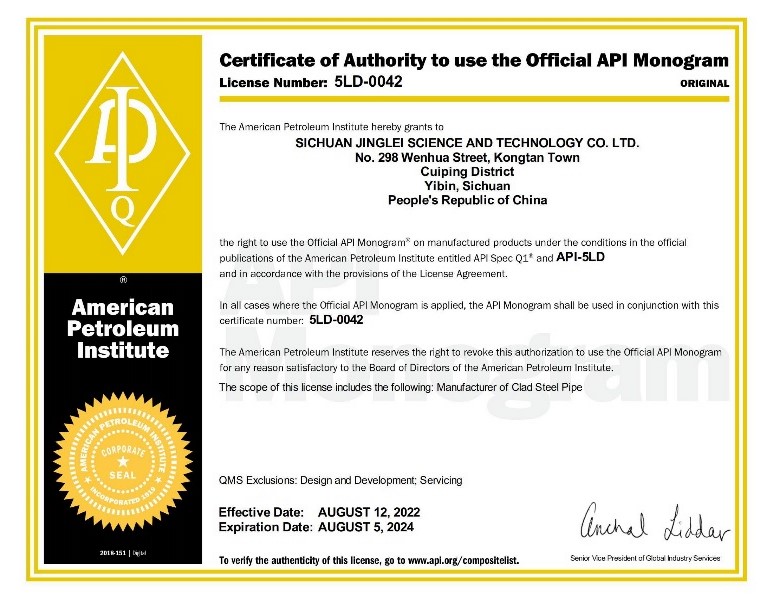

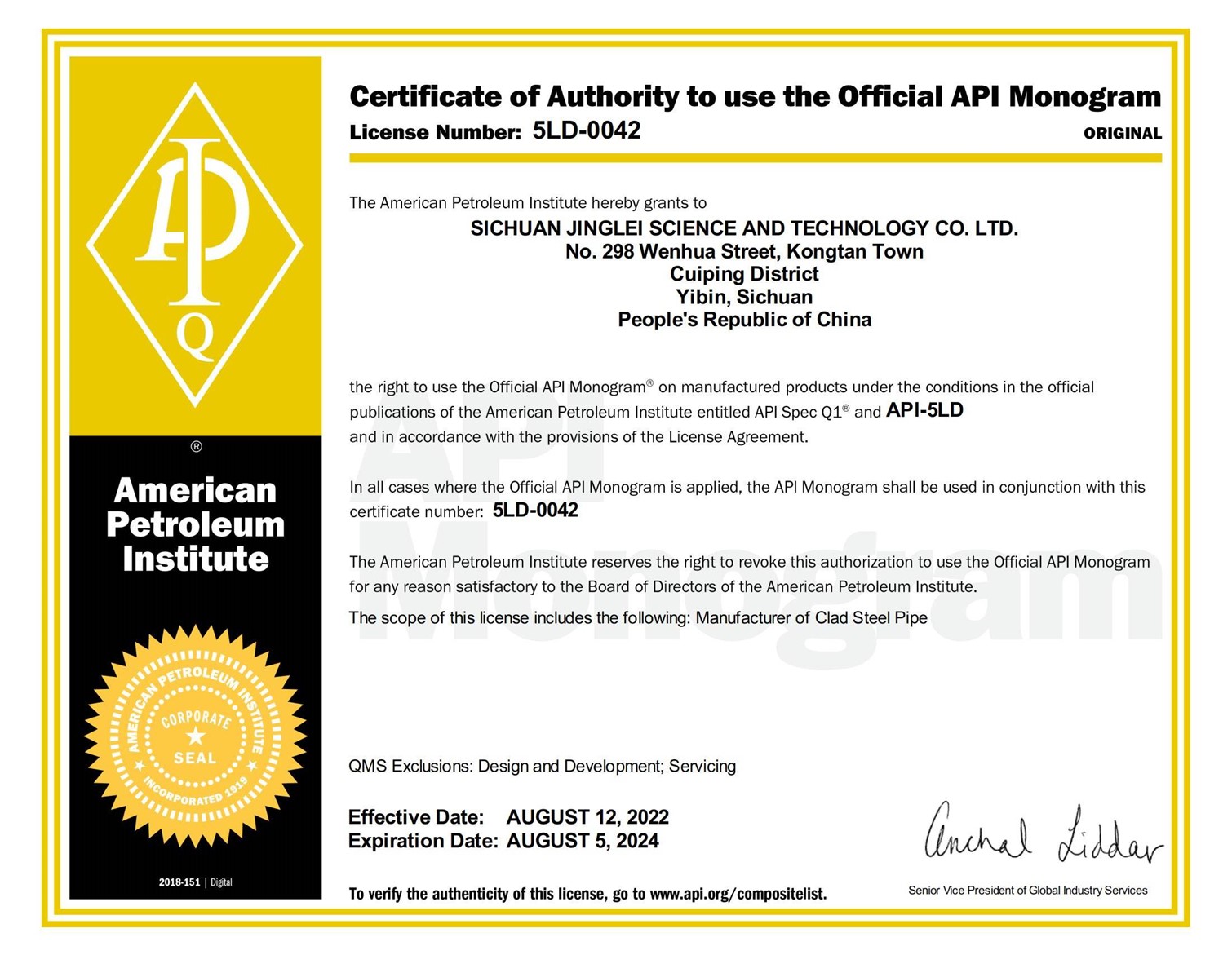

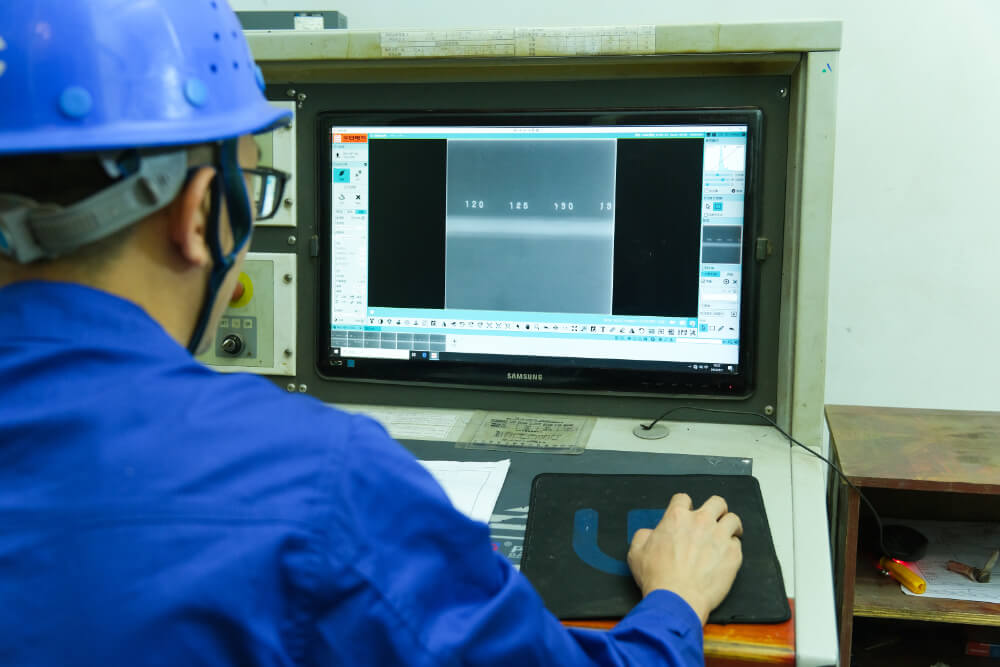

Certificate, Accreditations & Licenses

Application

Application

JLC Clad Pipes specializes in the manufacturing of a diverse range of clad pipes that cater to a wide range of applications across various industries.

Petrochemical Industry

Chemical Processing

Mining Industry

Desalination Plants

Oil and Gas Industry

Power Generation

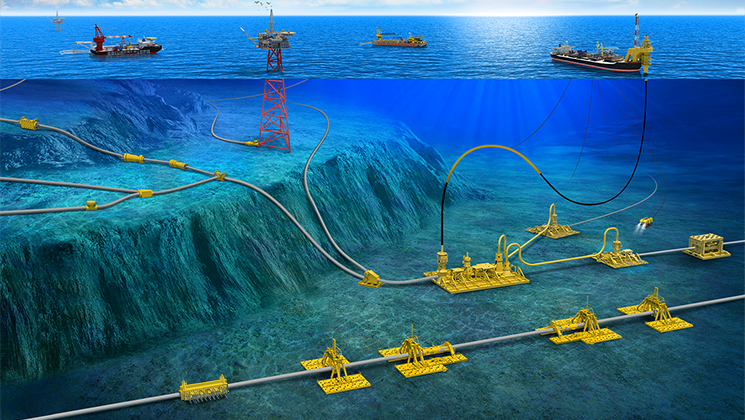

Offshore and Subsea Applications

Comparison

| CLAD PIPES | SOLID CRA PIPE | |

|---|---|---|

| Yes | Reduce Material Costs | No |

| Yes | Enhanced strength & durability for high temperature and high-pressure | No |

| Yes | Allow combination of different metals | No |

| CLAD PIPES | WELD OVERLAY PIPES | |

|---|---|---|

| Yes | Metallurgical Bond | No |

| Yes | Uniform Thickness | No |

| Yes | No Dilution | No |

| Yes | Reduced Risk of Disbondment | No |

| Yes | Cost- Effective | No |

| Yes | Enhanced mechanical strength and durability | No |

| Yes | Reduced Maintenance | No |

Why Choose

JLC CLAD PIPES

For superior performance, reliability, and corrosion resistance, choose JLC Clad Pipes as your trusted partner. Experience our world-class products and unlock your infrastructure’s full potential.

Trust JLC for unmatched strength, corrosion resistance, and reliability in critical applications.