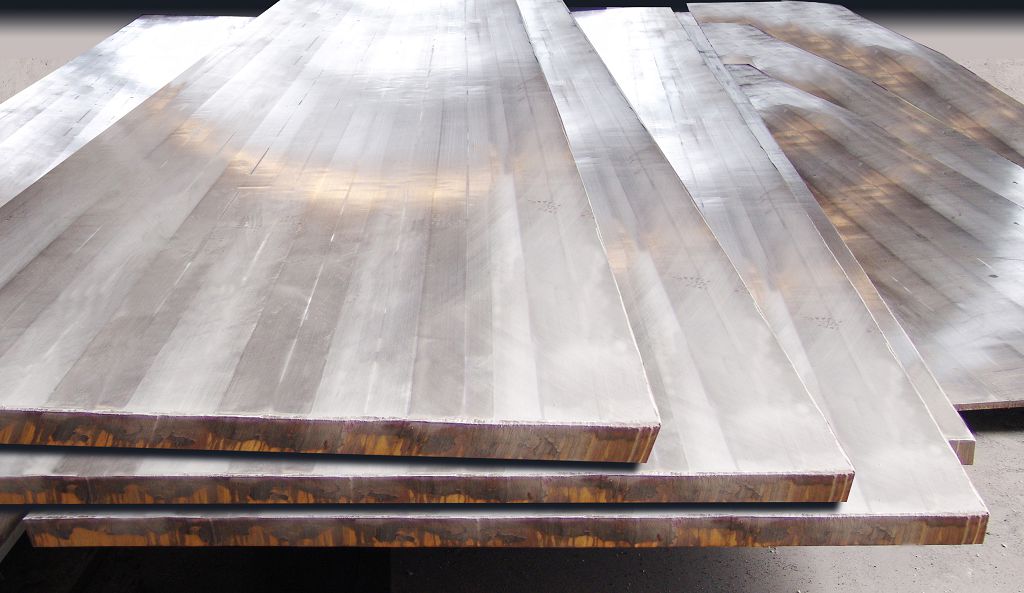

CLAD PLATES

Introducing JLC Clad Plates: unleash innovation and elevate pipeline performance

Introducing JLC Clad Plates: unleash innovation and elevate pipeline performance

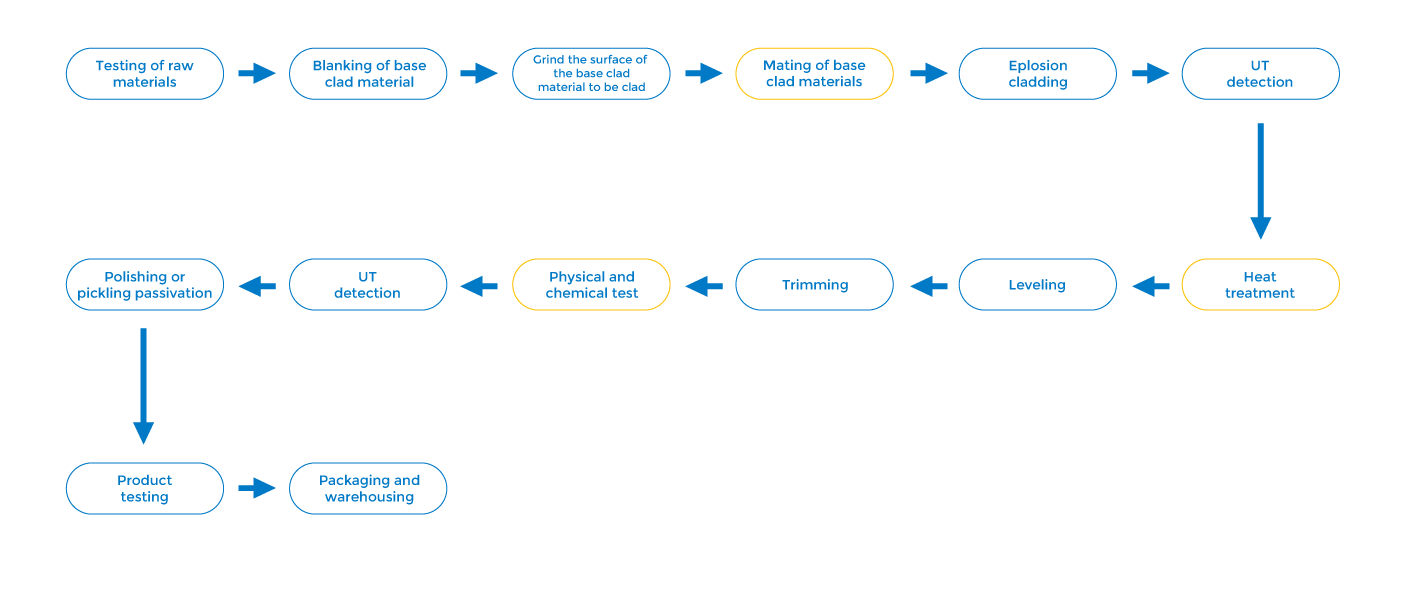

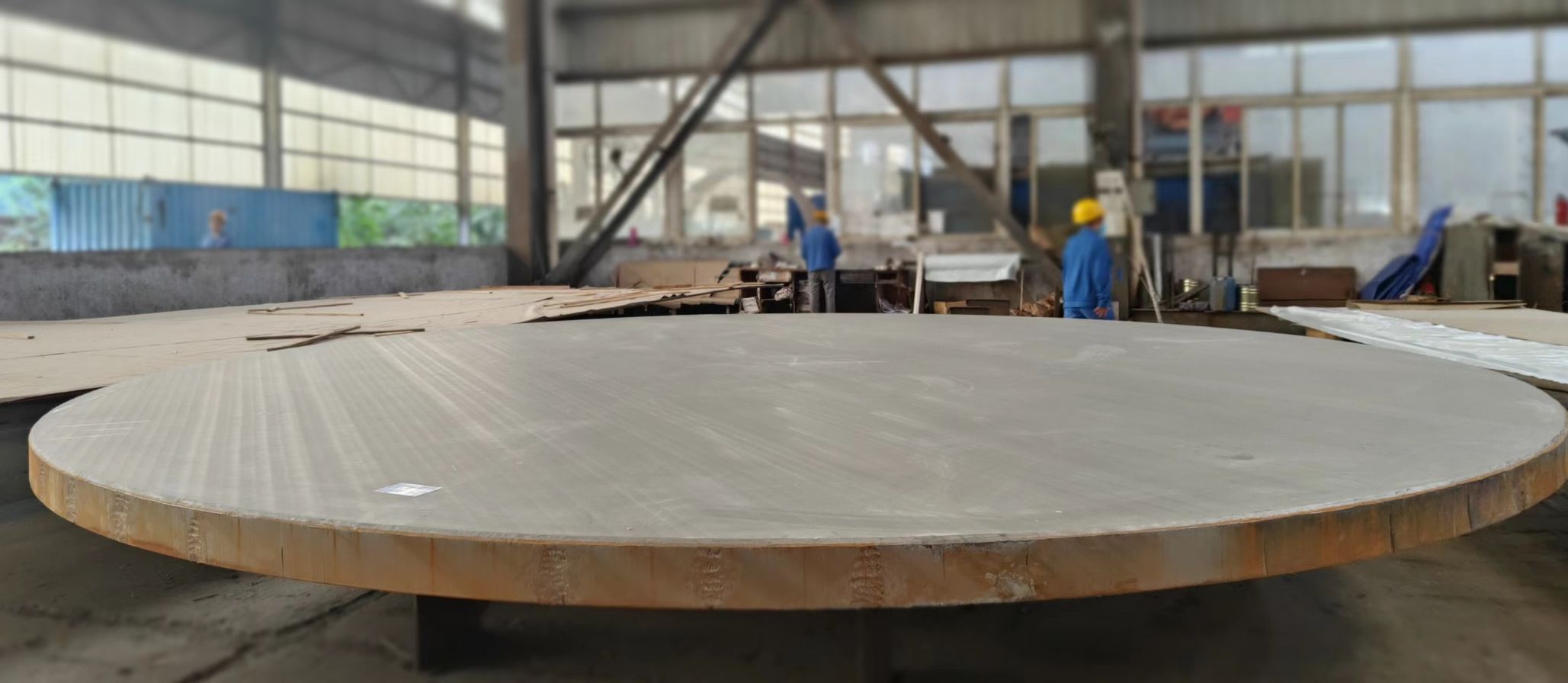

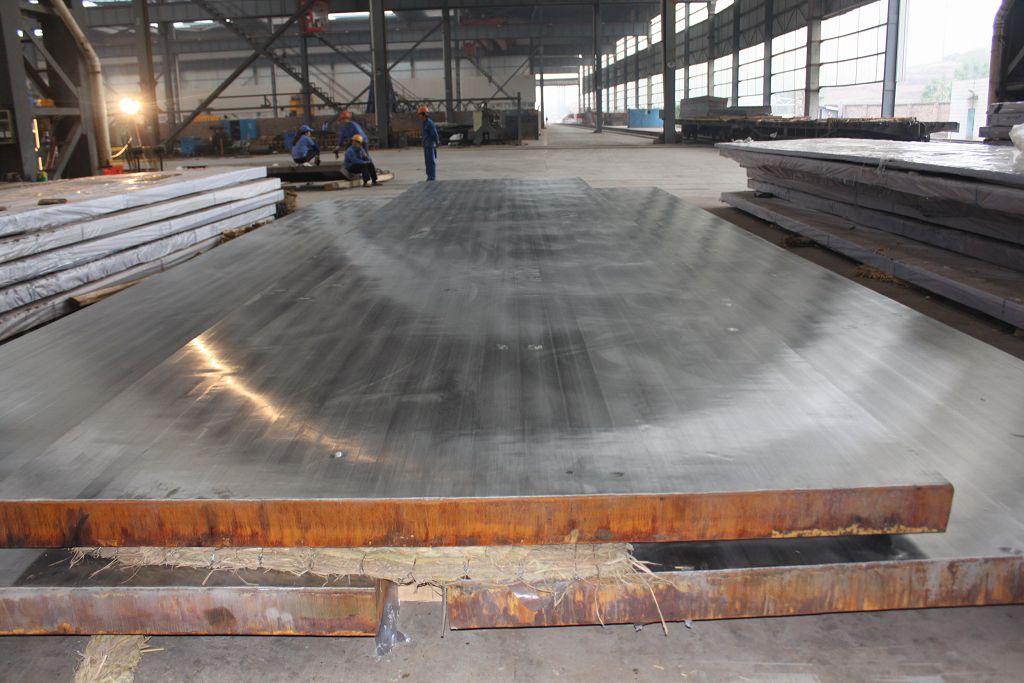

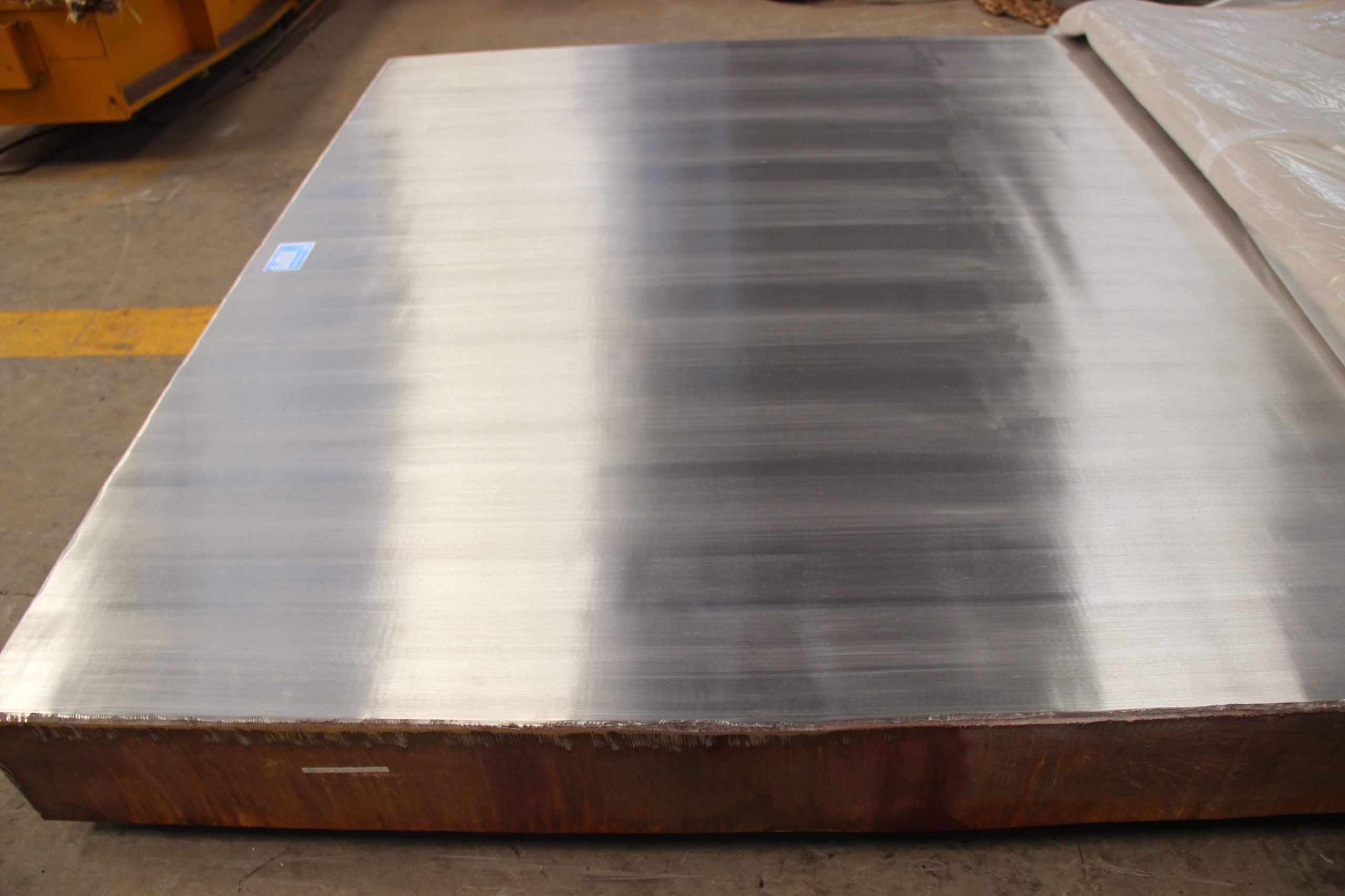

JLC is a pioneering manufacturer of clad plates using explosion welding technology. With a production capacity of 120,000 tons annually, JLC is the country’s largest company in this field. Our products conform to global standards like ASTM A263, A264, A265, B432, and JIS GS3601, G3602, G3603, G3604. Available in various sizes, they can be tailored to meet specific client requirements.

Partner with JLC CLAD PLATES

When it pertains to clad plates, JLC Clad Plates stands as your dependable ally. With our steadfast dedication to quality, resilience, and client contentment, we are poised to provide plates that transcend your anticipations. Embrace the distinction of our exceptional clad plates and unlock the full potential of your applications.

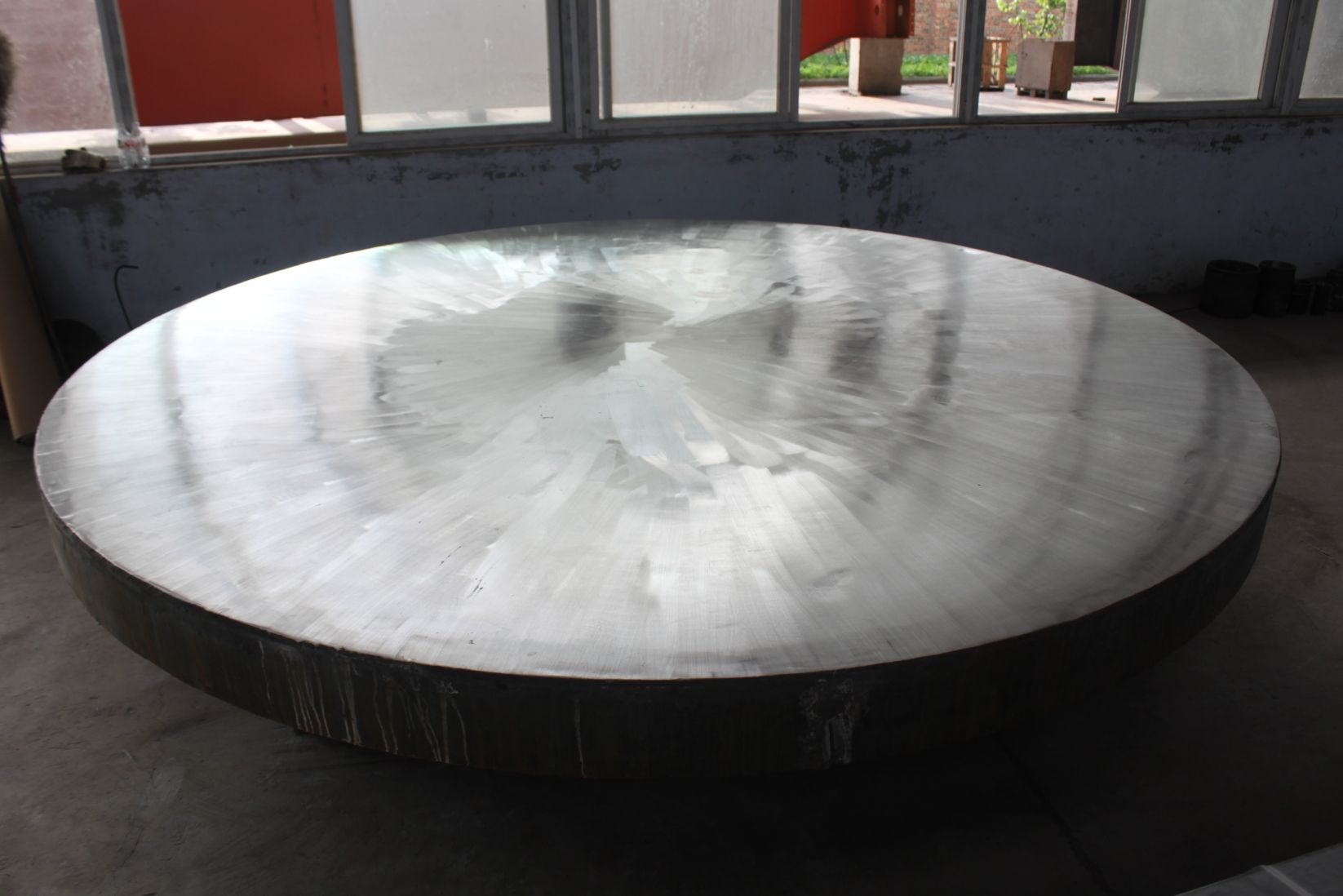

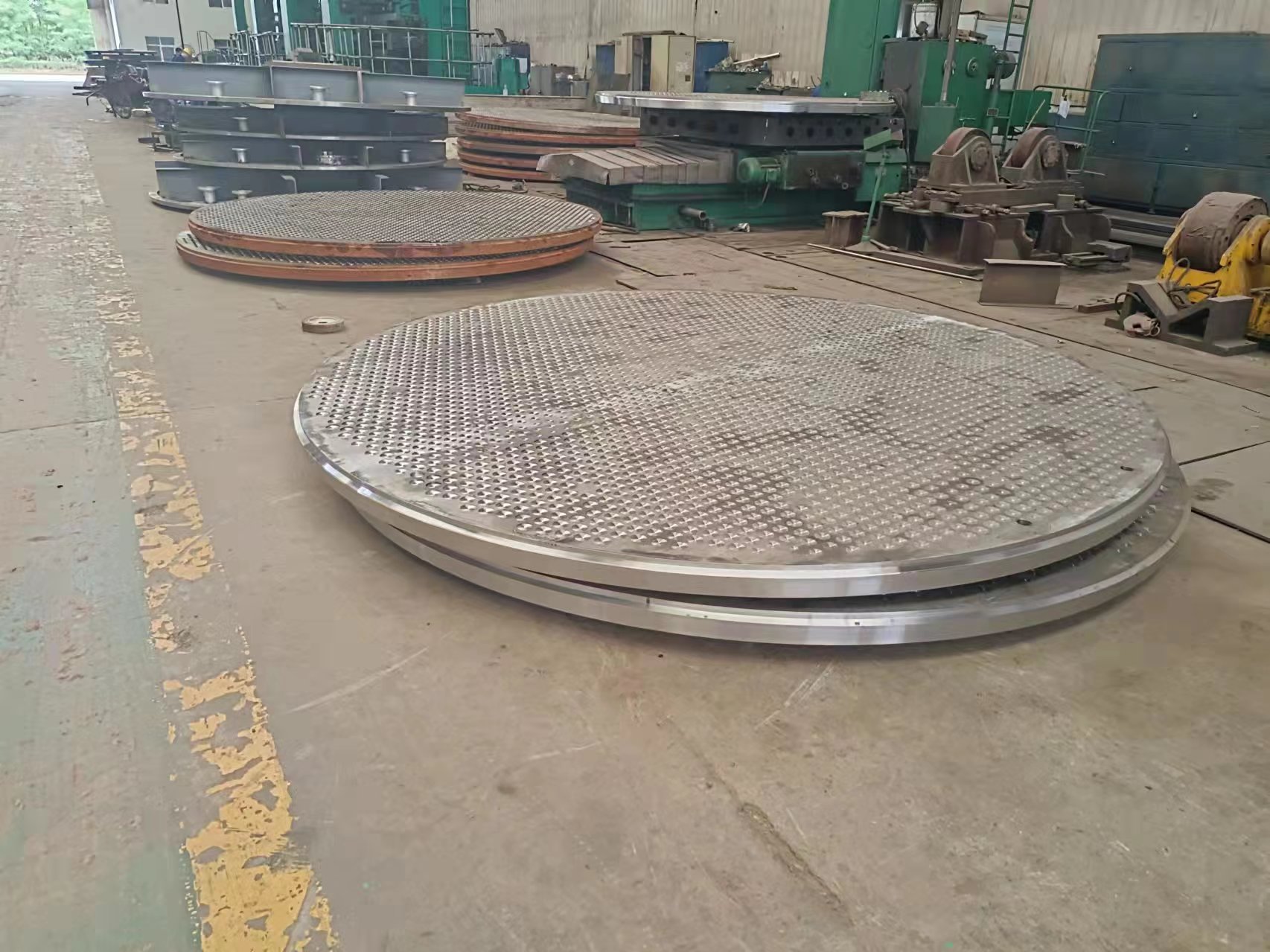

Products: Explosion Welded Clad Plate and Clad Tubesheet

| Product | Specification | Material Grade | Clad Plate – Thickness (mm) | Clad Plate – Length(mm) | Clad Plate – Width (mm) | Tubesheet |

|---|---|---|---|---|---|---|

| Titanium/Steel Clad Metal Plate | ASTM B898 | Cladding Metal: ASME SB265, ASTM B265 |

2-14 | 500~10000 | 500~2400 | Φ400~Φ4500 |

| Titanium/Steel Clad Metal Plate | ASTM B898 |

Base Metal: ASME SA36, SA105, SA182, SA266, SA350, SA387, SA515, SA516, SA533, SA537, SA240 ASTM A36, A105, A182, A266, A350, A387, A515, A516, A533, A537, A240 |

8 – 300 | 500~10000 | 500~2400 | Φ400~Φ4500 |

| Stainless Steel/Steel Clad Metal Plate | ASTM A263 ASME SA263ASTM A264 ASME SA264 |

Cladding Metal: 304, 309, 310, 316, 410, 904L |

2 -16 | 500~13000 | 500~3600 | Φ400~Φ4500 |

| Stainless Steel/Steel Clad Metal Plate | ASTM A263 ASME SA263ASTM A264 ASME SA264 |

Base Metal: ASTM A36, A105, A182, A266, A350, A387, A515, A516, A533, A537, A240 |

6 – 300 | 500~13000 | 500~3600 | Φ400~Φ4500 |

| Nickel/Steel Clad Metal Plate | ASTM A265 ASME SA265 |

Cladding Metal: ASME SB575, SB127, SB424, ASTM B575, B127, B424N6, NO4400, N06600, N10276, N06455, N02201, N06625, N06686, N06059, N08825, N08020, AL-6XN |

2 – 15 | 500~10000 | 500~2800 | Φ400~Φ4500 |

| Nickel/Steel Clad Metal Plate | ASTM A265 ASME SA265 |

Base Metal: ASME SA36, SA105, SA182, SA266, SA350, SA387, SA515, SA516, SA533, SA537, SA240ASTM A36, A105, A182, A266, A350, A387, A515, A516, A533, A537,A240 |

6 – 300 | 500~10000 | 500~2800 | Φ400~Φ4500 |

|

Copper/Steel Clad Metal Plate |

ASTM B432 |

Cladding Metal: |

2 – 14 | 500~8000 | 500~2500 | Φ400~Φ3500 |

| Copper/Steel Clad Metal Plate | ASTM B432 | Base Metal: ASME SA36, SA105, SA182, SA266, SA350, SA387, SA515, SA516, SA533, SA537, SA240ASTM A36, A105, A182, A266, A350, A387, A515, A516, A533, A537, A240 |

8 – 300 | 500~8000 | 500~2500 | Φ400~Φ3500 |